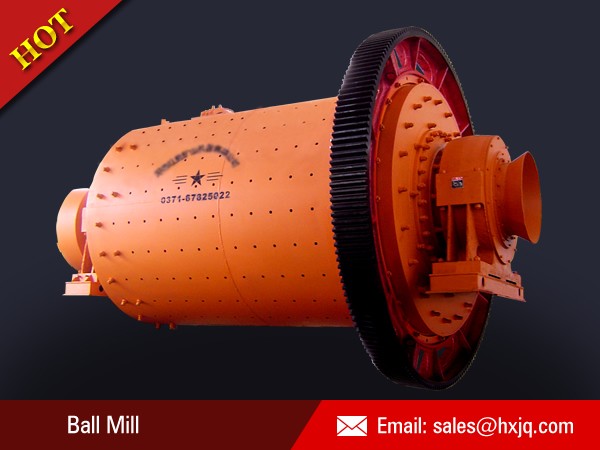

Henan Hongxing Mining Machinery Co., Ltd, as a leading mining machinery manufacturing enterprise in China, has decades of year's history in the ball mill developing field. So we could provide you with the most reasonable suggestions about the price and equipment parameters.

The first thing to do after buying the ball mill is to check if the accessories of each part are complete and qualified. Then install the equipment according to the illustration and the expert's suggestions. After the installment, the no-load and load test should be conducted to check if it can function normally. Here are some suggestions about the safe operation during the process:

1. The continuous running time of the no-load test should be more than 12-24 hours, and the problems which occur during the process should be dealt with in time.

2. The load test can be conducted after the equipment passes the no-load test and should be finished in steps or phases. The materials feeding should be in accordance with the discharging situation in the load test process, avoiding the unnecessary wear and damage to the steel balls and lining plate of the cylinder.

3. The load increase and test time should be determined by the functioning condition (temperature rising, noise and tooth surface contact) of the big and small gears and the reductor gears. The machine cannot perform the full load operation before the tooth surface reaches the required degree in the precision.

4. The cooling system, lubrication system, main bearing, transmission bearing and the reductor should operate normally.

5. Examine and fasten all bolts again after the 2/3 steel balls installed have had a trial run for 24-48 hours.

6. Keep a careful record of the details during the trial run.

The above things are the safety issues we may encounter in the operation. They also are the things most worthy to pay attention to.

We always serve customers with heart and soul.